The different processing methods of seafood after fishing determine the quality and price of seafood. To maintain the freshest taste of seafood, various processing methods have been explored, which are also widely used in the artificial breeding industry.

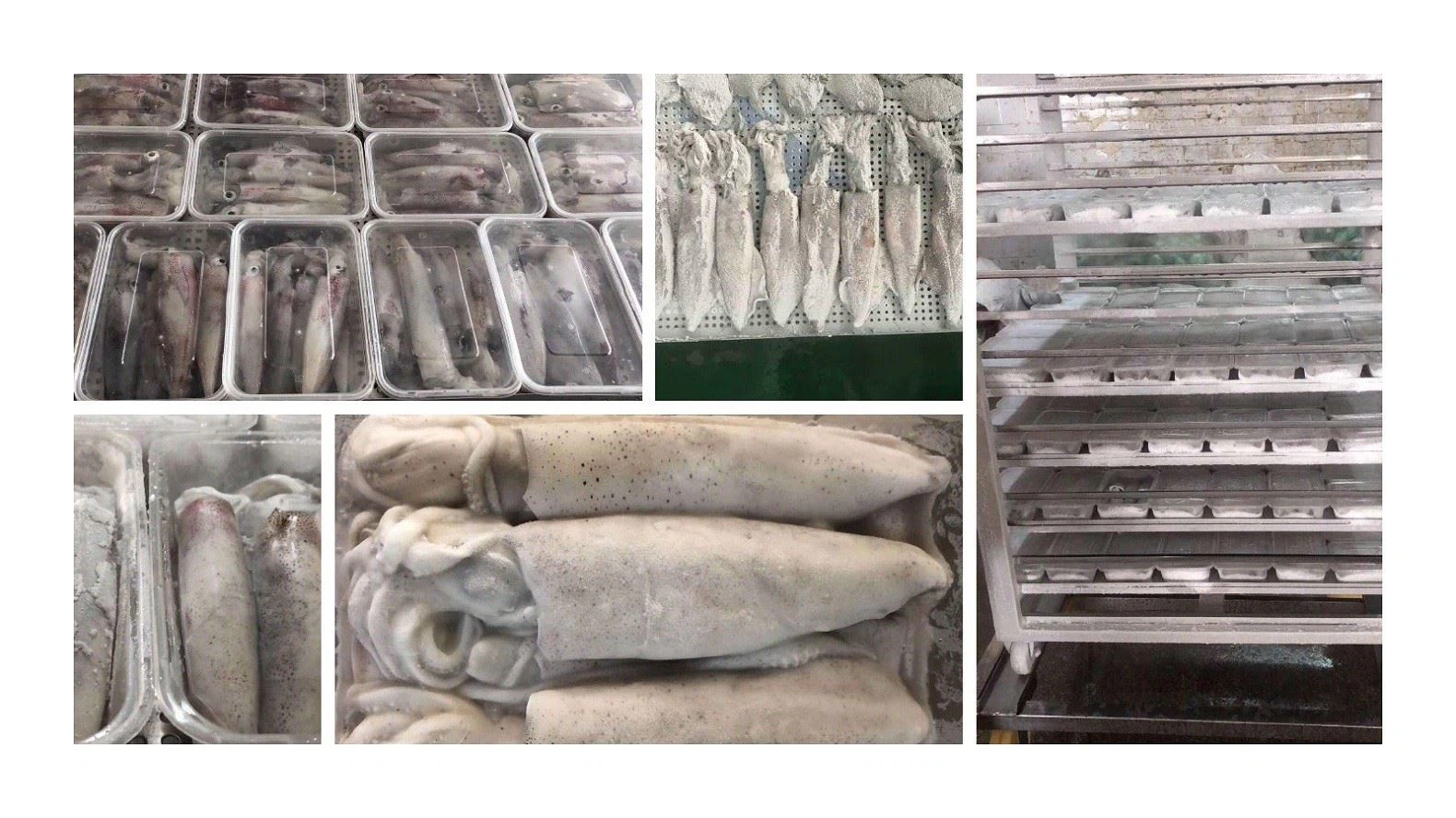

Due to the characteristics that seafood dies when they leave the water, high peak capacity and short freezing time,and the loss during the transportation is large, most sellers use chilling or freezing to store them for convenient transportation.

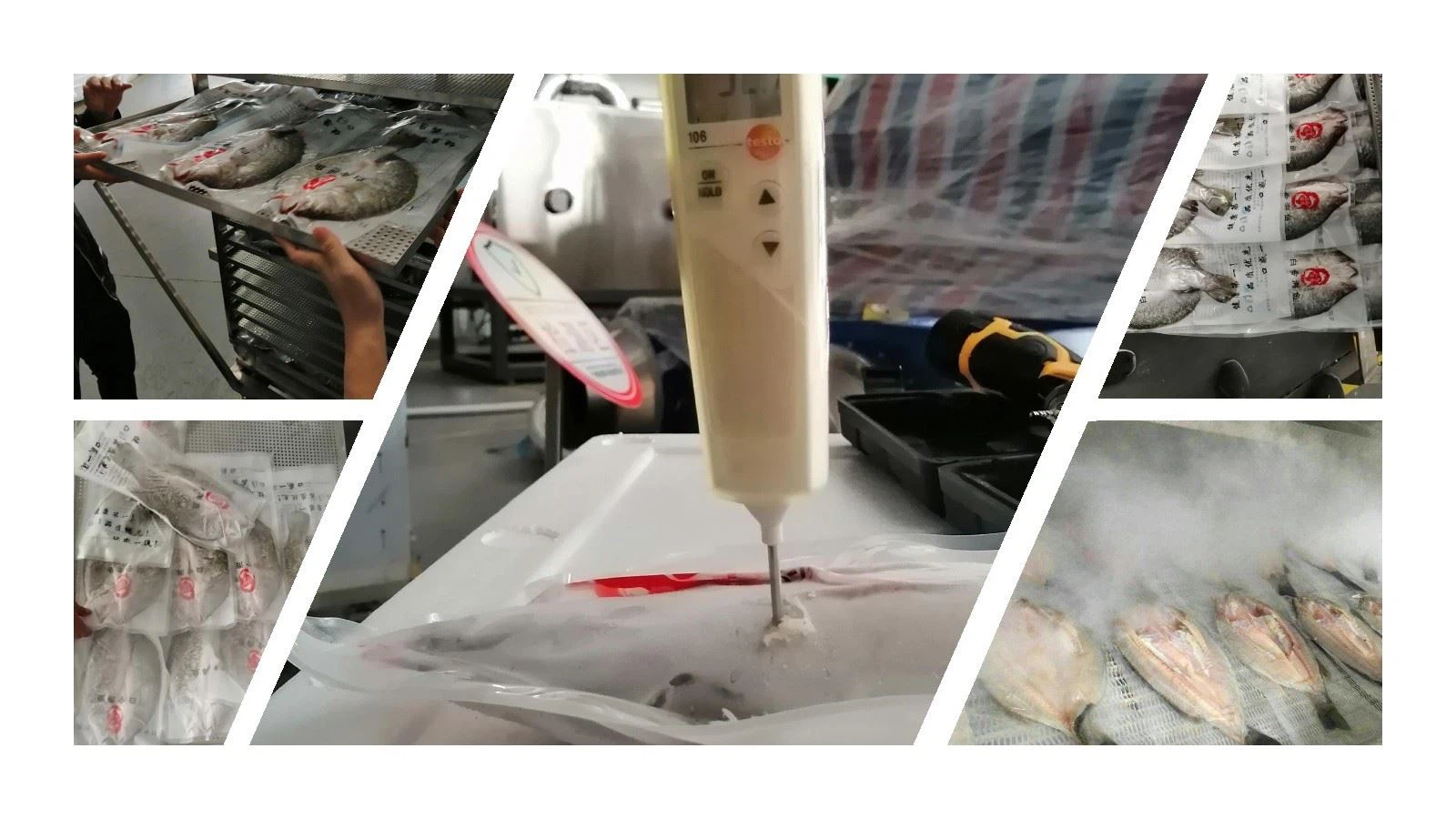

If you are near a seafood fishing point, buying live seafood is the best choice. However, for inland or far away from the fishing places, it is difficult to guarantee the survival rate and freshness of the seafood. For example, the most tenacious lobster can only last for 7 days during transit. It is better to use the latest and fastest liquid nitrogen quick-freezing technology for seafood preservation.

Although the chilled processing method is simple and low-cost, it can only be applied in short distances transit. Frozen seafood reduces the central temperature of seafood to -18°C through freezing technology to ensure the nutrition and quality of seafood. For the concern of parasites in seafood, some countries require that seafood must be frozen at a low temperature before selling on the market, to reduce the risk of infection.

Compared with the traditional quick-freezing machines, frozen seafood processed by liquid nitrogen quick-freezing technology can maximize the maintaining effect of the nutrition and moisture of seafood and preserve the original flavor. In addition, the liquid nitrogen quick-freezing technology can complete the entire freezing process in only 5-20 minutes, which can preserve the freshness of the seafood in the shortest time and increase the production capacity. The seafood produced in this way usually comes with excellent quality, and its sales price is relatively higher.