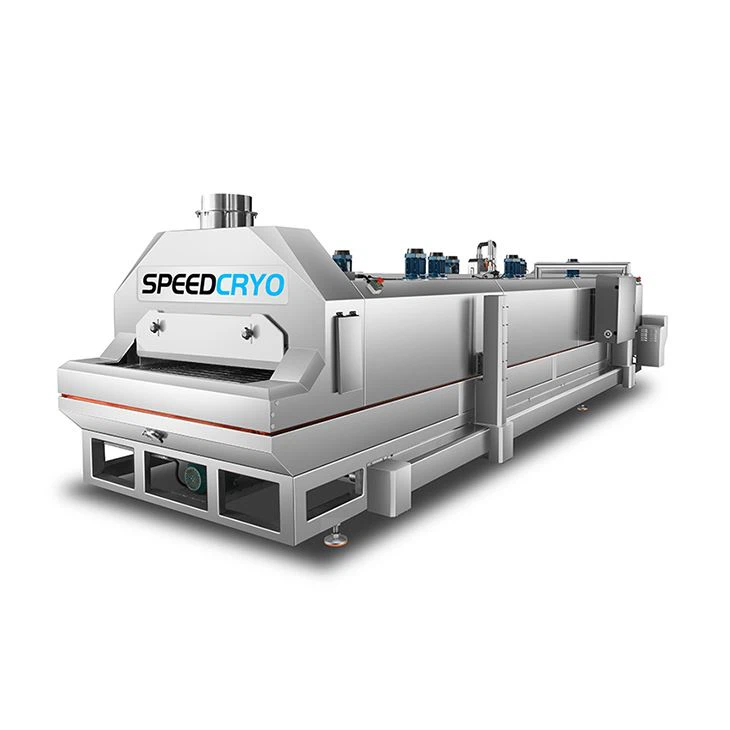

Tunnel Freezer

The tunnel-type cryogenic freezer offers highest flexibility according to your processing volume. The tunnel length and conveyor belt can be fully customized to fit any kind of automatic processing line. With auto-lift function, it can be easily cleaned and maintained.

What Is Tunnel Freezer?

A tunnel freezer (also known as a freezing tunnel) is an industrial device designed to freeze products quickly and evenly. It consists of a sealed chamber into which the food products are placed. They move through the tunnel by means of a conveyor belt system. Inside the chamber, cold air currents are generated to freeze the food items in a very short time, ordinarily within minutes.

Advantages of Tunnel Freezer

Rapid

freezing

The probably biggest

advantage of a

tunnel freezer is

its ability to

achieve

exceptionally rapid

freezing rates.

Cryogenic

temperatures enable

quick heat transfer,

allowing products to

be frozen within no

time. This rapid

freezing not only

preserves the

quality of the

product but also

enhances efficiency

in production

processes.

Product

quality

Cryogenic tunnel

freezers ensure a

uniform and

consistent freezing

process, preventing

the formation of ice

crystals within the

product. This

preserves the

texture, flavor, and

nutritional content

of the items being

frozen, resulting in

a superior end

product.

Versatility

across

products

One of the strengths

of a tunnel freezer

using cryogenic

technology is the

adaptability to a

wide range of

products. Whether

it's vegetables,

meat, pasta,

seafood, or baked

goods, the

adjustable freezing

parameters make it

possible to

accommodate various

product types

without compromising

quality.

A tunnel

freezer has a

space-efficient

layout

Tunnel freezers are

typically designed

with a compact and

space-efficient

layout. This is

particularly

beneficial for

industries where

floor space is at a

premium. The

streamlined design

allows for easy

integration into

existing production

lines.

Reduced

downtime

A cryogenic tunnel

freezer is designed

for continuous

operation,

minimizing downtime

during production.

The rapid freezing

process allows for a

constant flow of

products through the

freezer.

-

Liquid Nitrogen Cryogenic IQF Instant Freezer*CE Certificatesread more

*Totally Safe and Non-toxic

*Precise temperature control

*Energy-... -

Meat Cryogenic Tunnel FreezerShrimp Tunnel IQF Freezer*CE Certificatesread more

*Food Grade SUS 304

*Extreme Fast Freezing

*Low Maintaining CostSmall IQF Machine*Ultra Low Temperature -196℃read more

*Whole Body SUS 304

*Instant Freezing Tunnel

*Easy O...Small Cryogenic Freezing Tunnel*Working Temperature 0 ~ -196℃read more

*High Frozen Efficiency

*Small Area Covered

*Low dr...Small Shrimp Tunnel Instant Freezeer*CE Certificationread more

*Famous Brand in China

*Good Thermal Insulation

*Convenient in M...Small Shrimp Tunnel IQF Freezer*CE Certificationread more

*China Well-known Brand

*Meet the Food Quality Control Standard

...Industrial Small IQF Tunnel Freezer*CE Certificationread more

*Economic Price

*Low Initial Investment

*Low Failure Rate

...Small Conveyor Flash Freezer*CE Certificatesread more

*Favorable Price

*Short Processing Cycle

*Environmental Protectio...Small Seafood Quick Tunnel Blast Freezer*CE Certificatesread more

*Satisfactory Price

*Hard-wearing Components

*Precisely Temperatu...Industrial IQF Tunnel Quick Freezer*CE Certificatesread more

*High Machining Efficiency

*Production Flexibility

*Wear-resistant C...IQF Individually Quick Frozen Machine*CE Certificatesread more

*Strong & Durable

*Food Grade SUS 304

*One-year Warranty

Why Choose Us

Our factory

Founded in 1993, SPEEDCRYO is a

leading provider of cryogenic food

freezing solutions, offering

comprehensive cold chain products

and services globally.

Advanced equipment

We provide a range of freezing

equipment to efficiently meet

clients' food processing needs,

including cryogenic cabinet freezer

and tunnel individual quick

freezing. These technologies and

equipment have been widely used in

meat and poultry foodstuffs, baked

products, fruits and vegetables,

aquatic products and various

prepared dishes.

Rich experience

With over 28 years of experience in

food quick freezing, we offer

comprehensive and innovative

cryogenic solutions.

Customized services

Our team of experts will work

closely with you to understand your

needs and will provide solutions

that are tailored to meet your

expectations.

Types of Tunnel Freezer

Single-belt tunnel freezers

Single-belt tunnel freezers use one continuous belt to transport products through the freezing tunnel. This design is ideal for smaller production lines and products that require uniform freezing.

Multi-belt tunnel freezers

Multi-belt tunnel freezers feature multiple conveyor belts, allowing for higher production capacities. Each belt can operate at different speeds, accommodating various product types and sizes.

Spiral tunnel freezers

Spiral tunnel freezers utilize a spiral conveyor system to maximize space efficiency. This design is perfect for facilities with limited floor space but high production demands. The spiral configuration allows for extended freezing times without requiring a larger footprint.

Application of Tunnel Freezer

Frozen Food Industry

The frozen food industry uses tunnel freezers for quick freezing of a variety of products, from vegetables to meat and seafood.

Bakery Industry

Tunnel freezers are used to freeze dough, batter, and other baked goods to maintain quality and extend shelf life.

Pharmaceutical Industry

The pharmaceutical industry uses tunnel freezers to freeze and store medicines, vaccines, and other medical supplies.

Chemical Industry

Tunnel freezers are used for quick freezing of chemical products, including epoxies, adhesives, and resins.

Components of Tunnel Freezer

Conveyor belts

Transport products through the freezing tunnel.

Refrigeration units

Generate the cold air needed for rapid freezing.

Control systems

Manage temperature and airflow to ensure optimal freezing conditions.

Insulated enclosures

Maintain the low temperatures required for efficient freezing.

Regular cleaning and

inspection

Schedule routine cleaning and

inspection of the refrigeration

system. Remove debris, ice buildup,

and any other contaminants that

might affect the efficiency of the

cooling or freezing process.

Inspect the conveyor belts, fans, and other moving parts for wear and tear. Replace or repair components as needed to prevent unexpected breakdowns.

Optimal temperature

control

Monitor and control the temperature

consistently to ensure that the

system maintains the required

temperature levels for efficient

cooling or freezing. Regularly

calibrate temperature sensors and

controllers to guarantee accurate

readings and prevent variations that

could impact the quality of the

processed food.

Proper lubrication

Keep all moving parts

well-lubricated to reduce friction

and wear. This includes conveyor

belts, fans, motors, and other

components undergoing continuous

motion. Only use lubricants

recommended by the system

manufacturer and adhere to the

specified lubrication schedules.

Efficient airflow

management

Optimize airflow within the tunnel

to ensure uniform cooling or

freezing of products. Proper airflow

helps maintain consistent product

quality and reduces the risk of

uneven temperature distribution,

especially in high-speed

“blast” systems where

temperature reduction is primarily

initiated through airflow control.

Regularly clean and inspect air vents and fans to prevent blockages that can impede airflow.

Scheduled maintenance

shutdowns

Plan scheduled maintenance shutdowns

to conduct more in-depth inspections

and repairs. This proactive approach

can help identify potential issues

before they escalate, minimizing

downtime and extending the

system’s lifespan.

Employee training and

awareness

Train personnel on proper operating

procedures and the importance of

regular maintenance. Well-informed

staff can contribute to the early

detection of issues and the

implementation of preventive

measures.

How to Choose a Tunnel Freezer

Capacity and throughput: When evaluating a tunnel freezer, it is important to evaluate the capacity and throughput requirements of the operation. Understanding the volume of product to be frozen and the required freezing speed will help determine the appropriate size and configuration of the freezer to meet production needs.

Freezing performance and uniformity: Freezing performance and uniformity of tunnel freezers are key factors in maintaining frozen product quality. The freezer’s ability to reach and maintain the required temperature throughout the freezing process must be considered to ensure consistent and high-quality results for a variety of food products.

Energy efficiency and operating costs: Energy efficiency is an important consideration when selecting a tunnel freezer. Look for refrigerators with advanced insulation, efficient airflow design and energy-saving features to minimize operating costs and environmental impact while maximizing freezing efficiency.

Maintenance and cleaning: Ease of maintenance and cleanliness of your tunnel freezer are important to ensure smooth operation and product safety. Choose a freezer with easily accessible components, hygienic design features and easy-to-clean surfaces to simplify maintenance tasks and maintain food hygiene standards.

Adaptability and flexibility: Companies should consider the adaptability and flexibility features of tunnel freezers to accommodate different product types and packaging formats. Multifunctional freezers can be adjusted to different production needs and product specifications, providing added value and versatility to operations.

Differences between a tunnel freezer and a cold store

Cold store and tunnel freezers serve the same purpose: To house and preserve products at low temperatures. However, there are significant differences in their design and operation.

Freezing vs

temperature

maintenance

A tunnel freezer is used

to freeze goods rapidly,

taking them from ambient

to subzero temperatures

in a short period. In

contrast, the primary

function of a cold store

is to maintain products

at a low and constant

temperature —

usually above the

freezing point —

to extend their shelf

life and keep them

fresh.

Freezing vs

cooling

Tunnel freezers normally

operate at temps below

-1 ºf for rapid

freezing of goods. Cold

storage rooms, on the

other hand, tend to be

kept above 32 °f

(generally 32 °f to

41 °f, in line with

the products stored).

Short term vs long

term

Freezing tunnels are

designed to freeze goods

in a short period

— often in a

matter of minutes or

hours — as per the

product type and the

machine’s

capacity. Cold store

lend themselves more to

long-term storage since

they run at a constant

temperature, preserving

product quality.

Tunnel vs cold

store

Tunnel freezers are

long, narrow structures

through which products

are transported on a

conveyor belt or trays.

Cold store is typically

thermally insulated

rooms with cooling units

kept at a constant

temperature. Products

are stored inside the

room on cold store

racking.

Design and Mechanism of Tunnel Freezers

Tunnel freezers typically consist of an insulated enclosure equipped with a conveyor belt system that transports products through a controlled freezing zone. The products enter at one end, progress through the tunnel where they are exposed to cold air or cryogenic agents like liquid nitrogen, and emerge frozen at the opposite end.

The freezing tunnel operates using precision-engineered airflow systems that ensure even temperature distribution. Through directed cold air, quick-freezing temperatures are achieved, reducing the likelihood of ice crystal formation that can damage the product’s cellular structure.

Cryogenic vs. Mechanical Freezing

Cryogenic Tunnel Freezers utilize

cryogenic liquids — primarily

liquid nitrogen or carbon dioxide

— to achieve rapid freezing. As

the cryogenic liquid comes into contact

with the products, it rapidly absorbs

heat, vaporizes, and freezes the

products quickly.

On the other hand, mechanical freezing involves circulating refrigerated cold air over the products to gradually lower their temperature. While not as fast as cryogenic freezing, mechanical systems are more common and can be cost-effective for certain applications.

Both methods aim to preserve product quality and extend shelf life, but they do cater to different requirements based on production scale, the temperature thresholds, and the specific nature of the products being frozen.

Our Factory

Founded in 1993, SPEEDCRYO is a leading provider of cryogenic food freezing solutions, offering comprehensive cold chain products and services globally. From industrial freezers to automated conveying freezing tunnels, cold storage room, and refrigerated truck, our 30 years of expertise empower food manufacturers and processors worldwide with cutting-edge freezing technology.

Our certificates

FAQ

We're professional tunnel freezer manufacturers and suppliers in China, specialized in providing customized refrigeration equipment. We warmly welcome you to buy or wholesale high quality tunnel freezer for sale here from our factory. For price consultation, contact us.

blast freezer for chicken, iqf instant freezer, liquid nitrogen iqf freezer