1. Product Introduction

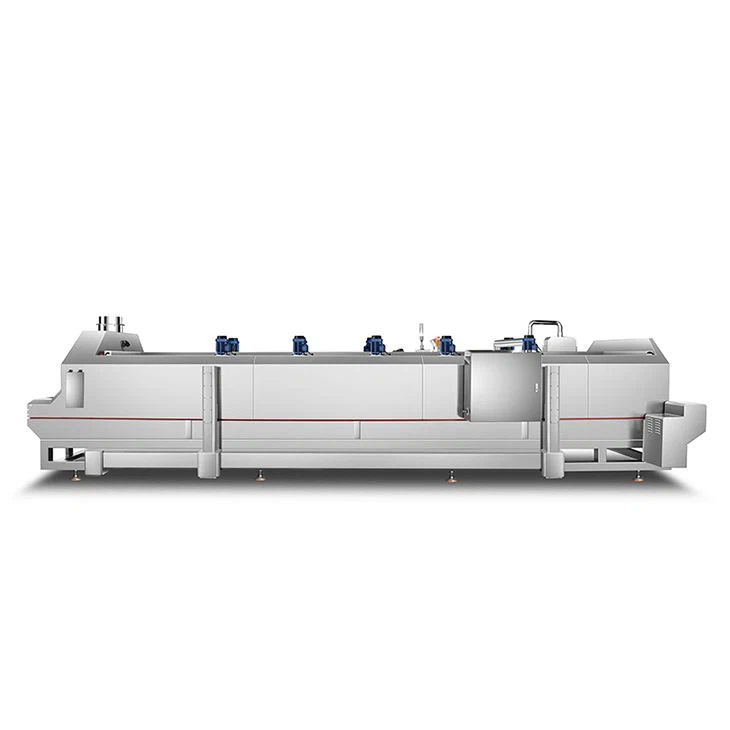

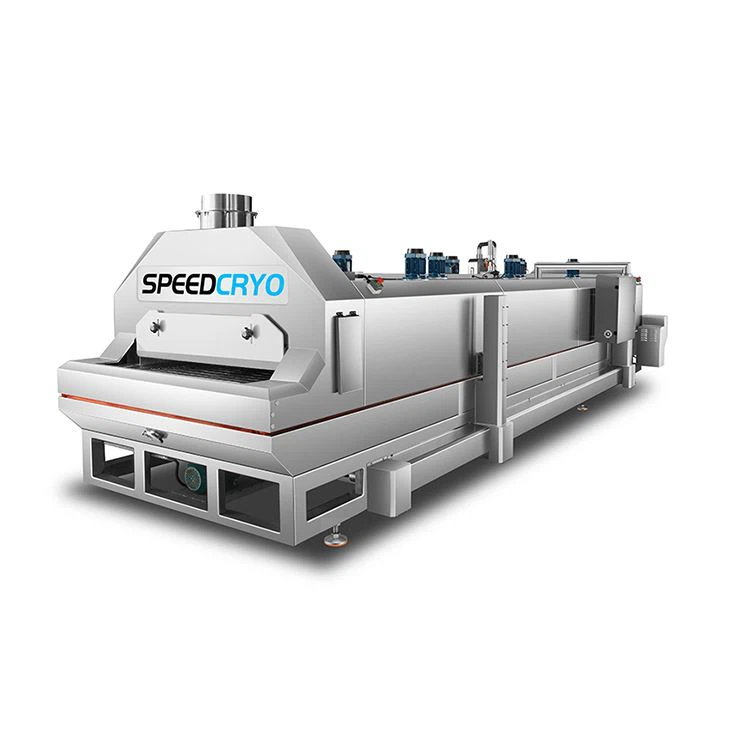

We design and manufacture individual quick freezing tunnel freezer using advanced liquid nitrogen freezing technology, in strict accordance with the requirements of HACCP, breaking the limit of working temperature -80℃ of conventional freezer. It provides multiple choices for customers as this series of products could be used in most of kinds of food processing, production capacity from 200 kg/h – 1300 kg/h. It could be design and manufacture according to customer’s actual requirements and space limitation.

2. Product Parameter

| Model: | JSSD-0712 Liquid Nitrogen Small IQF Freezer | ||

|---|---|---|---|

| Outer Size: | 722*218*204(cm) | Belt Size: | 700*120(cm) |

| Inlet Length: | 96(cm) | Outlet Length: | 50(cm) |

| Inlet Height: | Adjustable 5 ~15cm | Freezing Capacity | 500 ~ 750kgs/h |

| Weight: | About 2700 kgs | Voltage: | 380V |

| Material: | SUS 304 Food Grade | Power: | 8500W |

3. Products feature and application:

Many clients from Canada, Vietnam, Ecuador etc. use our shrimp iqf freezer freezing for Seafood.

Our shrimp iqf freezer could be customized according to existing shrimp peeling line, aquatic processing line or separated freezing line for shrimp. Within 10~30 minutes fast freezing, the cell structure of food will not be damaged, taste and appearance will be perfectly maintained.

4. Details information:

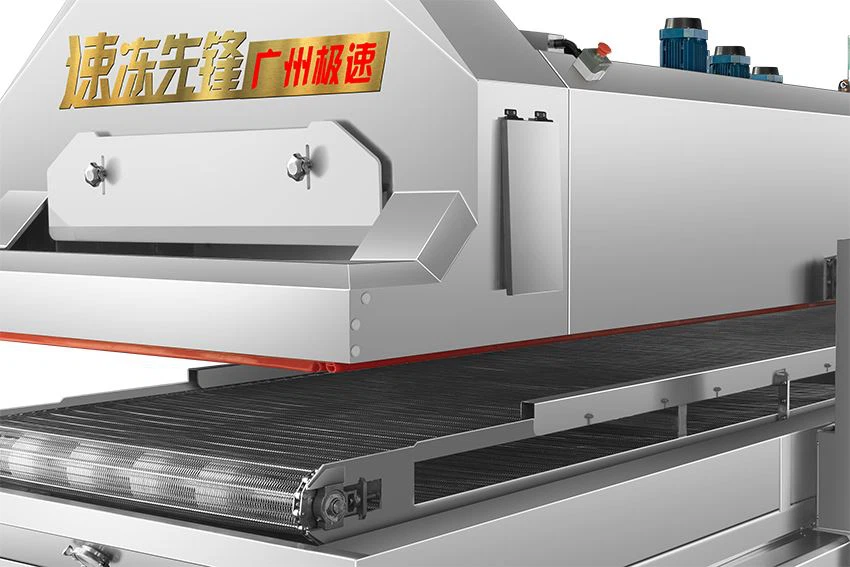

- Adjustable Inlet Height for Most of Kinds of Food

- Conveyor Belt 304 Stainless Steel

- Liftable Design for Easy Cleaning

- Special design process saves liquid nitrogen

- Set working temperature and time freely

5. Product Qualifications:

- CE Certificates

- ISO 9001 Certificates

- Specialization, modernization, large-scale standard production

- Own professional R&D technical team, installation and sales team

- Provide integrated services from design to production and installation

6. After sales support

Manufacturing, precise assembly and punctual delivery of liquid nitrogen individual quick freezing tunnel freezer have always been the sales philosophy we adhere to and follow. Even for the small IQF freezer ordered by each customer must undergo a period of operation and precise debugging before delivery. Once the tunnel freezer arrives at the customer’s production site, it can be put into production at any time.

7. FAQ

What is drip loss?

Drip loss is the phenomenon in unfreezing that the ice crystal melt inside of the food could not be absorbed by the cell but coming out as water.

The major reason for drip loss is ice crystal appeared, damaged the cell tissue and grew up in freezing.

Our liquid nitrogen individual quick freezing tunnel freezer could greatly reduce or minimize the ice crystal in freezing process. The drip loss rate of food is only 1%~2%, which is much less than the food frozen by conventional freezer 5~10%.