1. Product Introduction

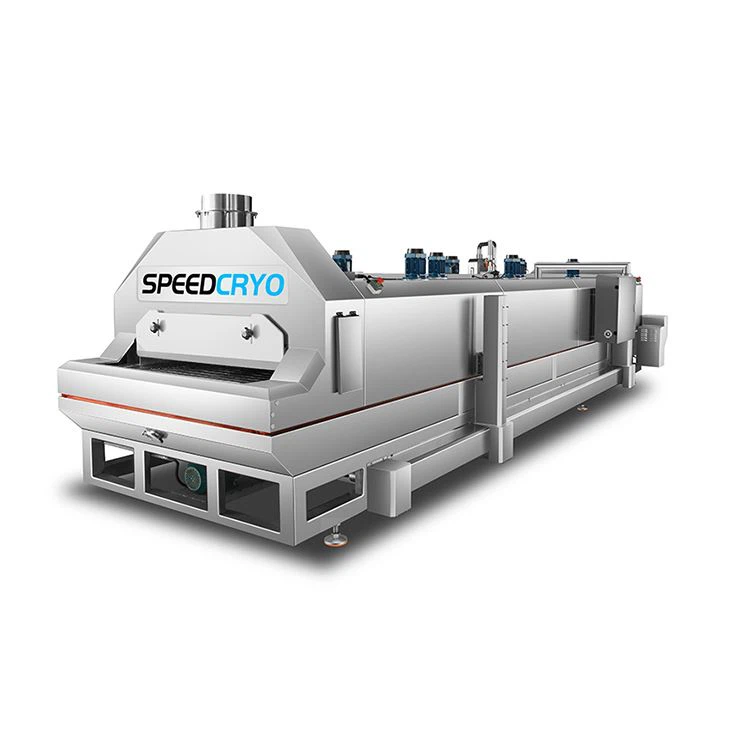

Cryogenic Meat Tunnel Freezers for Rapid High-Quality Freezing

Our cryogenic meat tunnel freezers use liquid nitrogen to instantly freeze meat and protein products at ultra-low temperatures. This rapid freezing method produces better quality, higher yields, and faster throughput compared to traditional mechanical freezing.

Advanced liquid nitrogen spray technology distributes cryogenic cold throughout the product, achieving full freezing in minutes. Conveyor belts transport meat continuously through the insulated freezing tunnel with customizable lengths. Intelligent controls regulate dwell time, temperature, and other parameters.

From whole muscle cuts to formed and processed meat, our meat tunnel freezers maintain exceptional texture, nutrition, and appeal. Moisture loss is minimized while extending shelf life. Reliable automation ensures consistent output ideal for high-volume production.

With over 20 years of food freezing expertise, we can customize tunnel specifications to your needs. CE-certified construction guarantees safety and longevity. Transition your protein freezing to our leading-edge cryogenic tunnel freezers for quality and efficiency gains.

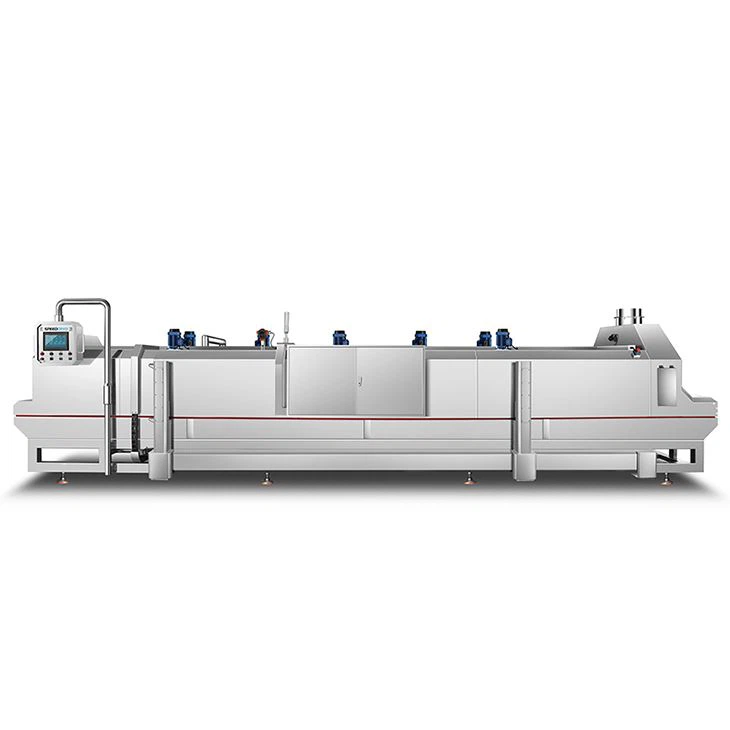

2. Product Parameter

| Model: | JSSD-0912 Liquid Nitrogen Cryogenic Tunnel Freezer | ||

|---|---|---|---|

| Outer Size: | 9.14*2.15*1.90(m) | Belt Size: | 9*1.2(m) |

| Entrance Length: | 0.96(m) | Outlet Length: | 0.5(m) |

| Inlet Height: | Adjustable 50 ~150mm | Freezing Capacity | 700 ~ 1000kgs/h |

| Weight: | About 4600 kgs | Voltage: | 380V |

| Material: | Whole Stainless Steel | Power: | 11000W |

3. Products Application:

Unmatched Freezing Speed and Quality for Meat Processing

Our cryogenic meat tunnel freezers fully freeze protein products in just 20-40 minutes, compared to the hours required for mechanical freezing. The ultra-fast freezing capacity freezes meat cuts, formed meats, and other items incredibly fast.

This rapid cryogenic freezing preserves the cellular structure and meat quality attributes completely. The quick freezing kinetics produce minimal intracellular ice crystals, avoiding damage from slow freezing methods.

That's why forward-thinking meat processors are adopting our cryogenic tunnel freezers, despite higher initial costs. The exceptional quality and throughput justify the investment for most high-volume operations.

4. Products Feature:

- Intelligent temperature control and monitoring

- Warning device for temperature over range

- Locks the moisture and reduces thawing loss in a very short time

- Greatly improve the rate of yield of frozen products

5. Product Qualifications:

- CE Certificates

- ISO 9001 Management System Certification

- Countless honor certificates and patent certificates gained in the past 31 years

- Mature quality management system

- Ultra-large scale production workshop

- Top-end Production Technology

6. About us

Leading Cryogenic Innovation for Over Two Decades

As an established pioneer in cryogenic food technology, we continually advance our systems through ongoing R&D. Our large team holds numerous patents and freezing best practices. By partnering with us, processors gain deep freezing knowledge and support.

Our specialists collaborate with you to engineer optimized cryogenic solutions for your goals. We stay on the cutting edge to bring you the latest freezing advances for a competitive advantage. Contact us today to freeze meat and proteins to new quality heights.

7. FAQ:

Should I pack meat before or after cryogenic freezing?

For most meats, packing prior to freezing is acceptable and will not significantly impact freezing times. However, post-freezing packing is recommended for certain products like seafood where moisture control is crucial. Our experts can advise the ideal workflow for your items to maximize quality and efficiency.